China Prefabricated Heavy Steel Structure Modular Stackable Ship Sea Shipping Container House Luxury Prefab Homes

The Window of Xi’an City–Building Steel Structure

Located at the southwest corner of the intersection of Tangxing Road and Tuanjun South Road in Xi’an Hi-tech Industrial Development Zone, City Window is a large-scale urban complex integrating offices, boutique international apartments, 24H trendy businesses and star hotels. The project is located in the West High-tech secondary entrepreneurship zone, with a planning area of 98 square kilometers, divided into the international software park, research and development park, new industrial zone, central business district of four major sections, three parks and one area of the development model.

Window of the City is located in the West High-tech second venture area of the International Software Park gateway location, Tangyan Road, the core of the creative industry belt hinterland, as one of the three north-south arteries connecting the Central Business District, the South Unity Road, north of Science and Technology Road, and the first phase of the High-tech mature living areas closely linked to the east of the golden corridor of business and the CBD and the CBD, the real realization of the results of the development of high-tech zone with the 21 years of development and the seamless docking of the city’s resources. It is the fusion point and connection point connecting the primary and secondary business areas of Hi-Tech Zone, and the throat and hub role of bearing the east and starting the west, leading the south and connecting the north will make this area become the front-runner and leader of Xi’an’s economic growth.

Construction Process Introduction:

Shenyang Huaqiang Jinlang City Square covers an area of 83,900 square meters with a floor area of 1.2 million square meters, including the 330-metre-high main tower “Big Corn”, the podium, and two buildings of 200 meters and 152 meters respectively. Huaqiang Jinlang City Square Building 1 building shape for the “two thin in the middle of the thick” spindle-shaped, is the first spindle-shaped building in the northeast region, rhythmic flow and stable volume interspersed with each other, so that the entire building shape in the space is more tense, to create a sense of the times and a sense of science and technology. In the construction of the core cylinder of Building 1 of the project, the project construction team of China Construction 8 adopted the “air building machine” – low-level multi-pivot intelligent overall jacking mould frame system.

The amount of concrete poured for Building 1 reached 32,000 cubic meters, which is a major breakthrough in the construction history of Liaoshen area. 11.9m thick raft slab for Building 1 is the first case of ultra-deep and ultra-thick mass concrete slab in Northeast China, and its shape was optimised from the initial round shape to the octagonal shape which is easier to construct. In terms of pouring method, the project construction team poured the raft slab in four times, reasonably dividing the pouring surface, optimising the concrete mix ratio, reasonably controlling the amount and time of each pouring, and adopting a special extended vibrating rod for local vibration to ensure the quality of the pouring.

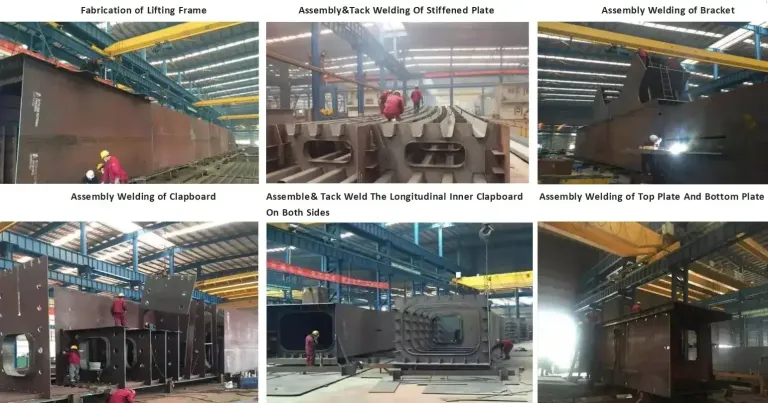

Production Process

With rich experience in bridge fabrication and installation, Honglu carried out effective on-site control from plate straightening, drilling, group welding, etc. …… and pre-assembled the bridge sections in the factory to ensure the high strength of the bridge. Installation accuracy of steel components during construction.

Rigorous on-site construction techniques

The excellent engineering management team carries out on-site construction in strict accordance with the approved special construction programme and operating procedures to ensure that all works achieve the objectives of high quality, high efficiency, low consumption, timeliness, safety and civilization.

Frequently Asked Question

Before cooperation, you may have the following questions.

-

Are you original manufacturer or trading company?

-

Is your price competitive compared with other companies?

-

Can you send engineers or whole team to install my project?

-

Do you accept container loading inspection?

-

What’s your work flow?

-

Can you provide architectural and structural design drawings?

Company Advantages

Steel structure manufacturer

Honglu, a steel structure top manufacturer with daily capacity 15,000+Tons, Effectively Shorten Construction Period And Saving Construction Costs For You.

efficient production

10 Production Sites, 400+ Production Lines, Annual Production Capacity Of Steel Structure 5,000,000+ Tons, Slabs 30,000,000㎡.

High quality service

Experiencing 21 Years, Serving 100,000+ Customers,Take The Lead In Passing ISO9001, ISO14001, OHSAS18001,Certification of European& American Standards.

Rich product chain

Rich Product Chains, One-Stop Service For Steel Structure Projects.

description2