Cobalt Welding Wire from Top Chinese Manufacturers: Quality & Services Unmatched

Elevate your welding projects with our premium Cobalt-Based Welding Wire. Engineered for superior performance in the most demanding applications, this wire is manufactured with meticulous attention to detail. Partnering with respected suppliers, our factory ensures each spool undergoes rigorous quality control, so you receive only the best. Ideal for aerospace, automotive, and energy industries, our welding wire guarantees exceptional durability and outstanding weld quality. Invest in a reliable solution that enhances your fabrication processes today.

Advantages Explained Cobalt-Based Welding Wire Is The Best in 2025

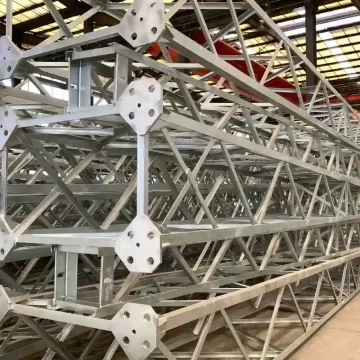

In 2025, the welding industry is witnessing a significant shift with the increasing popularity of cobalt-based welding wire. At Honglu Steel Structure, we understand that our clients seek materials that not only meet their technical requirements but also enhance overall performance and longevity. Cobalt-based welding wire excels in high-temperature applications, making it ideal for sectors like aerospace, automotive, and power generation. Its unique properties ensure exceptional corrosion resistance and reduced wear, giving it a competitive edge over traditional welding wires. Our commitment to excellence drives us to stay ahead of industry trends and meticulously analyze the needs of our clients. We recognize that each project comes with its own set of challenges, and cobalt-based welding wire offers tailored solutions that enhance productivity while maintaining stringent quality standards. By choosing this advanced welding material, global buyers can expect improved weld integrity and reduced downtime—a crucial consideration in today’s fast-paced production environments. At Honglu Steel Structure, we pride ourselves on not just being suppliers, but strategic partners in your success. Our team is ready to provide insights and support, ensuring that you can fully leverage the advantages of cobalt-based welding wire for your applications. By prioritizing your unique needs, we aim to make your procurement process smoother and your projects more successful, laying the groundwork for long-term partnerships in a rapidly evolving market.

Advantages Explained Cobalt-Based Welding Wire Is The Best in 2025

| Advantage | Description | Material Type | Best Use Cases |

|---|---|---|---|

| High Durability | Cobalt-based wires withstand extreme conditions and resist wear. | Cobalt Alloy | Aerospace components, oil drilling machinery. |

| Excellent Corrosion Resistance | Ideal for environments exposed to harsh chemicals. | Cobalt-Chromium | Marine applications, chemical processing. |

| Superior Weldability | Easy to use, providing strong and reliable welds. | Cobalt-Nickel | Precision engineering, medical devices. |

| Thermal Stability | Maintains integrity under high-temperature conditions. | High-Temperature Cobalt Alloy | Jet engines, nuclear reactors. |

| Versatility | Suitable for multiple applications across industries. | Various Cobalt Compositions | Automotive, aerospace, construction. |

Must-Choose Reasons Cobalt-Based Welding Wire Your End-to-End Solution Supplies the World’s Top Brands

J

James Thompson

I was genuinely impressed with the quality of the product. The attention to detail is top-notch, and the customer service team was extremely helpful throughout the purchasing process.

02 July 2025

L

Laura Collins

This purchase was a great decision. The item is well-made, and the customer service team went above and beyond to provide assistance.

28 June 2025

S

Steven Allen

Exceptional product quality! I was particularly impressed with the responsiveness of the service team.

08 May 2025

T

Timothy Harris

Great quality product! The after-sales support was timely and extremely helpful.

11 June 2025

J

Jessica Lee

Thrilled with the quality! The professionalism and responsiveness of the service team were greatly appreciated.

28 May 2025

S

Sophia King

Very satisfied with my choice! The customer service was proactive and very professional.

21 May 2025