High-Quality Copper-Nickel Welding Wire Manufacturer in China | Reliable Supply & Service

Our premium Copper-Nickel Welding Wire is designed for a wide range of industrial applications. Manufactured in trusted facilities in China, our welding wire adheres to the highest quality standards, ensuring exceptional performance in your welding tasks. We understand the complexities in sourcing reliable welding materials, and our selection is specifically crafted to cater to your requirements.

Best Practices For Copper-Nickel Welding Wire Your Trusted OEM Partner Pioneers in the Field

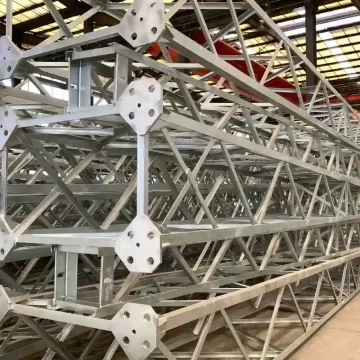

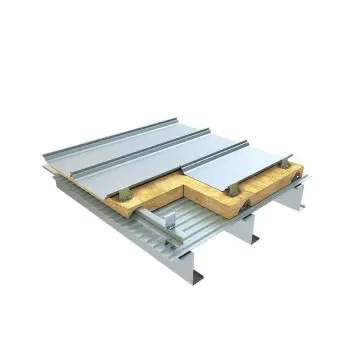

When it comes to copper-nickel welding wire, selecting the right OEM partner can significantly impact the success of your projects. At Honglu Steel Structure, we pride ourselves on being pioneers in the field, dedicated to delivering exceptional products and services tailored to meet the unique requirements of our clients. Our extensive experience in the industry has equipped us with the knowledge to understand the intricate needs of global procurement professionals. Best practices for copper-nickel welding wire include ensuring material compatibility, optimizing welding techniques, and maintaining strict quality control throughout the production process. At Honglu, we emphasize innovation and precision, employing advanced technologies and rigorous testing protocols to deliver welding wire that meets the highest industry standards. Our commitment to excellence goes beyond mere product delivery; we work closely with clients to provide customized solutions that foster project success. As your trusted OEM partner, we are committed to building lasting relationships and ensuring that your specific needs are met with unwavering dedication. Choose Honglu Steel Structure for not just superior products, but also a partner who genuinely understands and invests in your success. Together, we can pave the way for innovation and efficiency in your welding applications.

Best Practices For Copper-Nickel Welding Wire

| Practice | Description | Benefits | Recommended Wire Diameter (mm) |

|---|---|---|---|

| Proper Cleaning | Ensure base materials are clean and free from contaminants before welding. | Improves weld quality and reduces defects. | 0.8 - 1.2 |

| Controlled Heat Input | Maintain appropriate heat levels to avoid warping and excessive dilution. | Ensures structural integrity of the joint. | 1.0 - 1.5 |

| Use of Filler Material | Select appropriate filler material compatible with base metals. | Enhances bond strength and corrosion resistance. | 0.9 - 1.4 |

| Post-Weld Treatment | Implement post-weld heat treatment to relieve stresses. | Improves mechanical properties and service life. | 1.0 - 1.5 |

| Quality Control | Implement inspection processes to detect defects early. | Reduces rework and maintains compliance with specifications. | 0.7 - 1.3 |

Best Options For Copper-Nickel Welding Wire Leads the Global Market Pioneers in the Field

M

Michael Anderson

The product arrived on time and in perfect condition. I appreciated the professionalism of the support staff during the entire process.

08 June 2025

S

Samantha Lee

The craftsmanship is impressive! The customer service team displayed a strong understanding of the product.

03 July 2025

S

Sunshine Johnson

Extremely pleased with the quality! The support staff was very friendly and professional.

11 May 2025

N

Nicole Carter

Absolutely love this item! The support staff was outstanding, making sure I had all the information I needed.

31 May 2025

H

Hannah King

Very pleased with this investment! The quality is superb, and the customer service was very supportive.

21 June 2025

J

Jack Smith

This product is fantastic! The quality is excellent and the service team was very knowledgeable and supportive.

30 May 2025