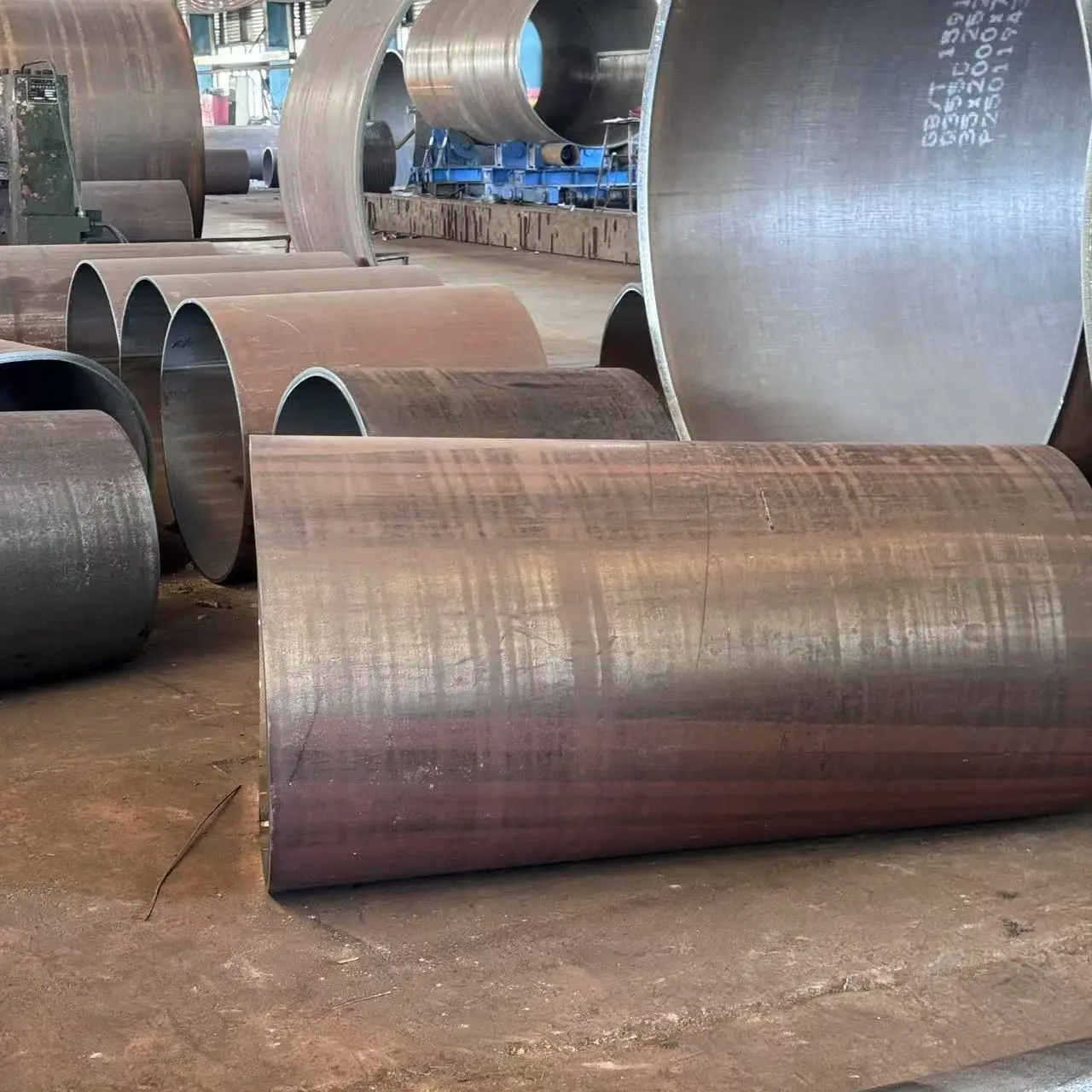

Corrosion-Resistant Holu JCOE Steel Pipe for Constructions

Manufacturing Process Excellence

The JCOE manufacturing process involves four precision stages:

|

J-Forming |

Steel plates are pre-bent into a distinctive "J" shape at both edges |

|

C-Forming |

The J-shaped plate is further formed into a "C" shape |

|

O-Forming |

The C-shape is closed into a perfect circular form |

|

Expanding |

Final calibration ensures perfect roundness and uniform wall thickness |

This controlled forming process minimizes residual stresses and creates pipes with:

Exceptional concentricity (≤1% ovality)

Consistent wall thickness (±0.5mm tolerance)

Superior mechanical properties throughout the pipe body

Technical Specifications & Standards

Materials: API 5L (Gr. B to X80), ASTM A106, A53, A333

Sizes: 18" to 80" OD (457-2032mm), Wall thickness 6-40mm

Lengths: Standard 6-12m, custom lengths up to 18m

Pressure Ratings: Up to 25MPa (3625psi)

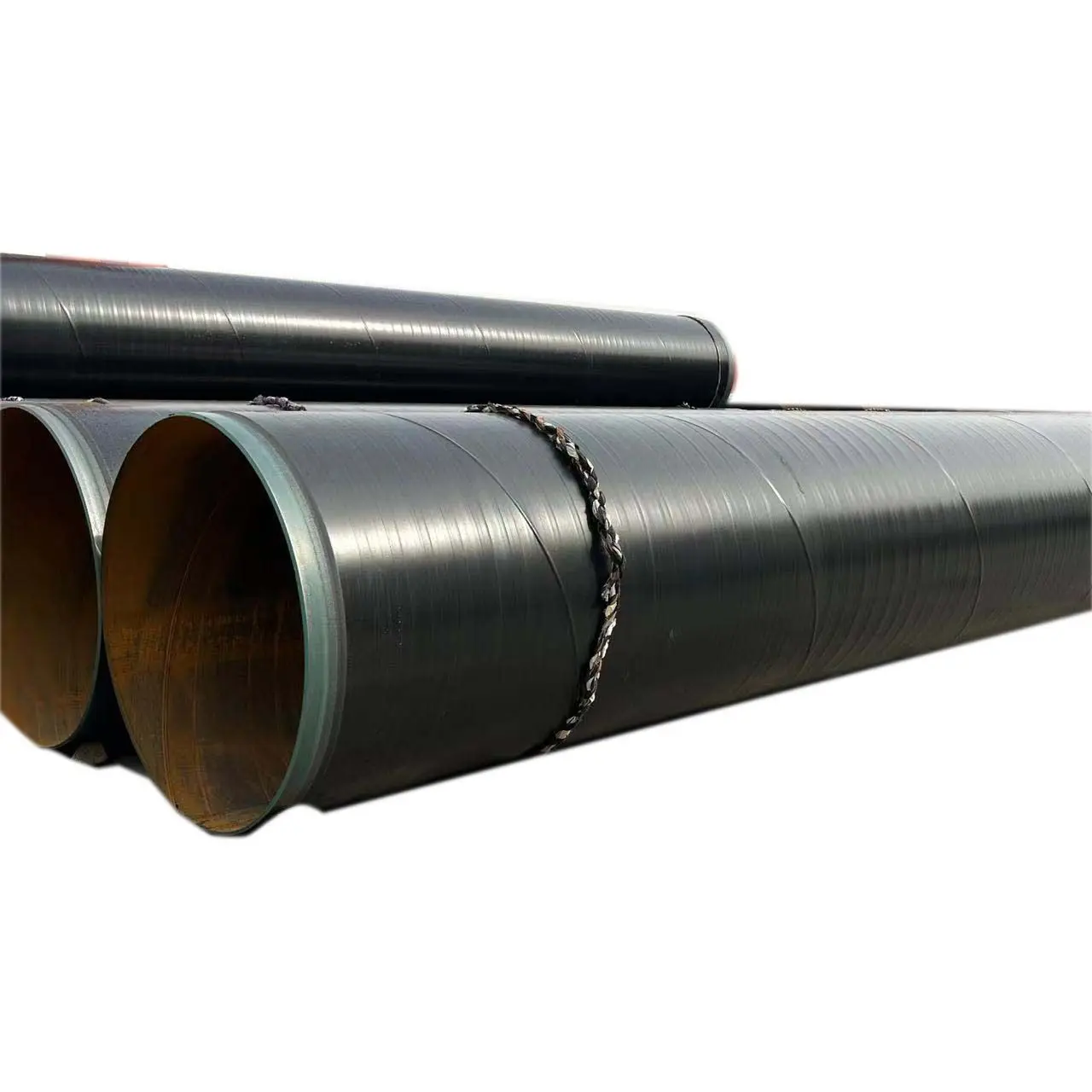

Surface Treatment: Beveled ends, internal/external coatings available

Key Advantages

|

Enhanced Structural Integrity |

The cold-forming process improves yield strength by 10-15% compared to conventional pipes |

|

Superior Weld Quality |

Precisely formed seams allow for flawless welding integrity |

|

Material Efficiency |

Optimized production reduces scrap by up to 20% |

|

Corrosion Resistance |

Compatible with FBE, 3LPE, and other advanced coatings |

|

Cost Efficiency |

Lower total cost of ownership through extended service life |

Applications

JCOE pipes are the preferred choice for:

|

Oil & Gas Transmission |

Mainline pipes, gathering systems |

|

Petrochemical Plants |

Process piping, effluent systems |

|

Power Generation |

Boiler tubes, condenser piping |

|

Water Infrastructure |

Large-diameter water mains, penstocks |

|

Mining |

Slurry pipelines, tailings disposal systems |

Quality Assurance

Our JCOE pipes undergo rigorous testing including:

100% ultrasonic testing (UT).

Hydrostatic testing to 1.5x working pressure.

Charpy impact testing for low-temperature applications.

Full traceability from raw material to finished product.

Why Choose Our JCOE Pipes?

With strict process controls and advanced manufacturing technology, our JCOE pipes deliver:

30% longer service life than conventional ERW pipes.

Reduced installation costs due to perfect roundness.

Reliable performance in extreme conditions (-46°C to 450°C).

Certified to ISO 9001, API 5L, and ASME standards.

Conclusion

For engineers and project managers who demand the highest quality pipeline solutions, JCOE pipes offer the perfect combination of strength, precision, and reliability. Whether for high-pressure transmission lines or critical process piping, our JCOE technology ensures optimal performance throughout the pipe's service life.

Frequently Asked Question

Before cooperation, you may have the following questions.

-

Are you original manufacturer or trading company?

-

Is your price competitive compared with other companies?

-

Can you send engineers or whole team to install my project?

-

Do you accept container loading inspection?

-

What’s your work flow?

-

Can you provide architectural and structural design drawings?

Company Advantages

Steel structure manufacturer

Honglu, a steel structure top manufacturer with daily capacity 15,000+Tons, Effectively Shorten Construction Period And Saving Construction Costs For You.

efficient production

10 Production Sites, 400+ Production Lines, Annual Production Capacity Of Steel Structure 5,000,000+ Tons, Slabs 30,000,000㎡.

High quality service

Experiencing 21 Years, Serving 100,000+ Customers,Take The Lead In Passing ISO9001, ISO14001, OHSAS18001,Certification of European& American Standards.

Rich product chain

Rich Product Chains, One-Stop Service For Steel Structure Projects.

description2