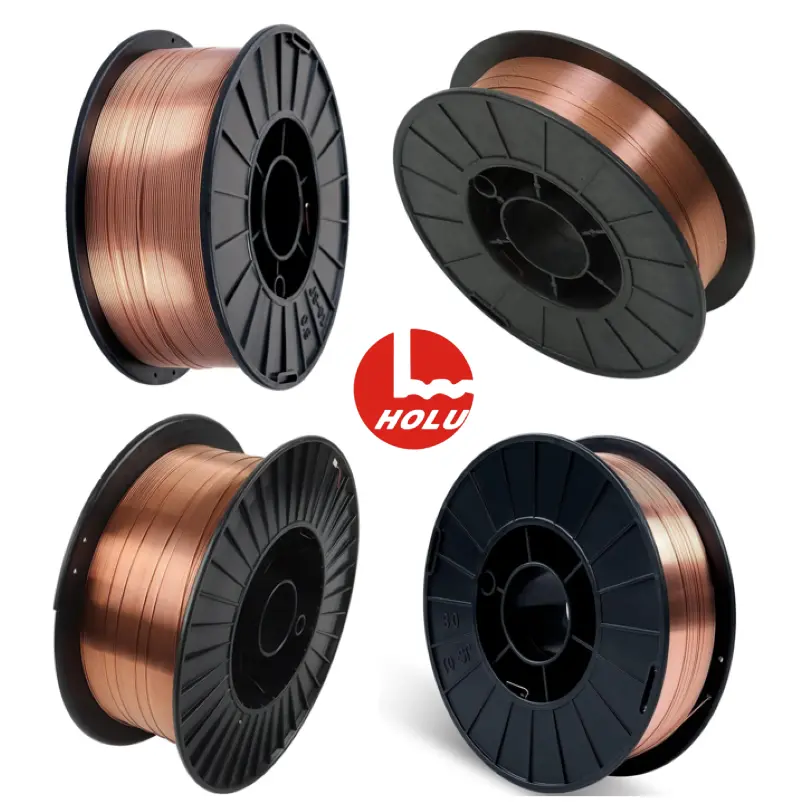

Gas shielded welding solid wire

Gas-shielded solid welding wires are widely used in various industrial applications due to their high efficiency, excellent weld quality, and adaptability to automated welding processes. These wires are typically made from mild steel, stainless steel, or other alloyed materials and require an external shielding gas (such as CO₂, Argon, or mixed gases) to protect the molten weld pool from atmospheric contamination.

Key Features

1.High Deposition Rates: Solid wires enable faster welding speeds compared to flux-cored or stick electrodes, improving productivity.

2. CleanWelds: The absence of flux reduces slag formation, resulting in smoother, spatter-free welds with minimal post-weld cleaning.

3.Versatility: Suitable for different welding techniques, including MIG (Metal Inert Gas) and MAG (Metal Active Gas), making them ideal for automotive, shipbuilding, and structural fabrication.

4.Good Mechanical Properties: Proper gas shielding ensures strong, ductile welds with low porosity and crack susceptibility.

Common Shielding Gases

CO₂: Economical and provides deep penetration, but may increase spatter.

Argon (Ar): Delivers stable arcs and clean welds, often used for stainless steel and aluminum.

Mixed Gases (e.g., Ar + CO₂): Balances penetration and spatter control, enhancing weld appearance.

Applications

Gas-shielded solid wires are extensively used in:

Automotive manufacturing (body panels, exhaust systems)

Pipeline construction

Heavy machinery and structural steel welding

Aerospace and precision engineering

Advantages Over Other Methods

Efficiency:Continuous wire feeding reduces downtime.

Precision:Better control over weld bead geometry.

Cost-Effectiveness: Lower operational costs due to reduced waste and rework.

Conclusion

Gas-shielded solid welding wires offer a reliable and efficient solution for high-quality welding across industries. By selecting the appropriate wire composition and shielding gas, welders can achieve optimal performance, durability, and aesthetic result.

Frequently Asked Question

Before cooperation, you may have the following questions.

-

Are you original manufacturer or trading company?

-

Is your price competitive compared with other companies?

-

Can you send engineers or whole team to install my project?

-

Do you accept container loading inspection?

-

What’s your work flow?

-

Can you provide architectural and structural design drawings?

Company Advantages

Steel structure manufacturer

Honglu, a steel structure top manufacturer with daily capacity 15,000+Tons, Effectively Shorten Construction Period And Saving Construction Costs For You.

efficient production

10 Production Sites, 400+ Production Lines, Annual Production Capacity Of Steel Structure 5,000,000+ Tons, Slabs 30,000,000㎡.

High quality service

Experiencing 21 Years, Serving 100,000+ Customers,Take The Lead In Passing ISO9001, ISO14001, OHSAS18001,Certification of European& American Standards.

Rich product chain

Rich Product Chains, One-Stop Service For Steel Structure Projects.

description2