01

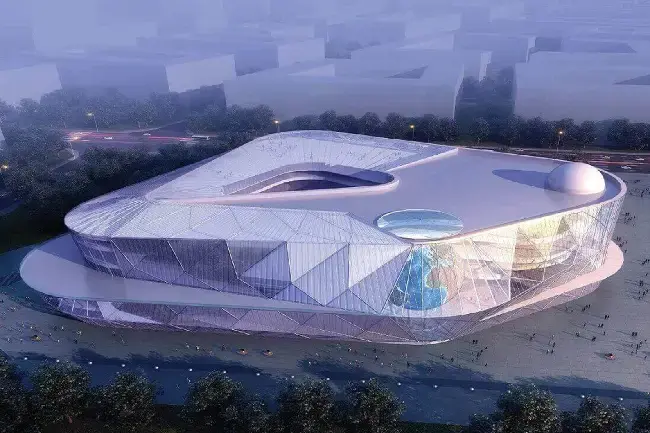

Guizhou Astronomical Space Time Tower

2025-04-11

01

The Astronomy Space Time Tower project is located in Hanglong Village, Pingtang County, Qiannan Prefecture, Guizhou Province. The single antenna radio telescope, the 500 meter aperture spherical radio telescope FAST, is situated here

The Astronomy Space Time Tower project is located in Hanglong Village, Pingtang County, Qiannan Prefecture, Guizhou Province. The single antenna radio telescope, the 500 meter aperture spherical radio telescope FAST, is situated here.

As one of the supporting projects of the “Tianyan Scenic Area”, the Astronomy Time and Space Tower has a total investment of about 200 million yuan, a building area of about 621 square meters, and a total construction area of about 3615 square meters. The construction tower is 99.99 meters high, with a base radius of about 23 meters. The first level of the tower base is 5 meters and the second level is 18 meters. The outer diameter of the ground tube of the Astronomy Time and Space Tower is 18 meters. There is a 10 meter cantilever platform at 15 meters of the tower body and an 8-meter cantilever platform at 80 meters. The top of the tower is a 19.99-meter-high skylight, which is an iconic building of the Astronomy Town. The tower also has a cantilever platform, 3D movie screen, VR exhibition hall, etc. The top of the tower can also be equipped with an indoor sightseeing hall, bungee jumping, gliding and other extreme sports.

As one of the supporting projects of the “Tianyan Scenic Area”, the Astronomy Time and Space Tower has a total investment of about 200 million yuan, a building area of about 621 square meters, and a total construction area of about 3615 square meters. The construction tower is 99.99 meters high, with a base radius of about 23 meters. The first level of the tower base is 5 meters and the second level is 18 meters. The outer diameter of the ground tube of the Astronomy Time and Space Tower is 18 meters. There is a 10 meter cantilever platform at 15 meters of the tower body and an 8-meter cantilever platform at 80 meters. The top of the tower is a 19.99-meter-high skylight, which is an iconic building of the Astronomy Town. The tower also has a cantilever platform, 3D movie screen, VR exhibition hall, etc. The top of the tower can also be equipped with an indoor sightseeing hall, bungee jumping, gliding and other extreme sports.

Honglu Steel Structure

is responsible for the production and installation of this project. The

tower has 27 floors above ground and 1 floor underground. The project

adopts a steel frame and support structure, and the structural form is

mainly circular pipe columns arranged in a ring shape. The sightseeing

platform has a conical structure, and the project schedule is tight, the

requirements are high, and the production difficulty is high. The steel

plate is 40mm thick, and the material is Q345B. The steel column is

welded with a large amount of full penetration welding. The deformation

and shrinkage of the steel column after welding have brought some

difficulties to the processing and welding. There are many connection

beams, support brackets, and intersecting line branches on the column

body. It is difficult to assemble the spatial angle and size of the

brackets and branch pipes, and the assembly angle and size errors will

bring inconvenience to the subsequent on-site installation. The company

conducts technical briefings with factory technicians and construction

personnel before processing, and develops processing technology plans to

ensure that the welding quality of components meets engineering design

requirements.

The construction of this project was carried out by the company adhering to the principles of “high standards, high quality, and strict requirements”, scientific management, overtime work, and the spirit of striving for the construction period. We strive to contribute to the key project construction of the Tourism Development Conference in a good and fast manner.

The construction of this project was carried out by the company adhering to the principles of “high standards, high quality, and strict requirements”, scientific management, overtime work, and the spirit of striving for the construction period. We strive to contribute to the key project construction of the Tourism Development Conference in a good and fast manner.