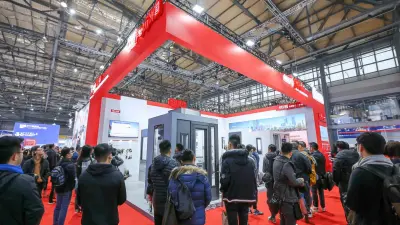

Advanced Real-Time Weld Monitoring Solutions for OEMs and Factories

Enhance the integrity of your welding processes with our high-quality Real-Time Weld Monitoring solutions. Designed to ensure superior weld quality, our robust system provides real-time tracking and analysis, significantly minimizing defects and maximizing productivity. Instant feedback allows you to make immediate adjustments, leading to improved performance. Partnering with HONGLU Steel Construction Group guarantees access to reliable technology that excels in challenging environments. Invest in a solution that prioritizes quality, safety, and efficiency for your welding operations. Together, we can elevate your welding standards to new heights!

The Secret to Real-Time Weld Monitoring Factory For the Current Year

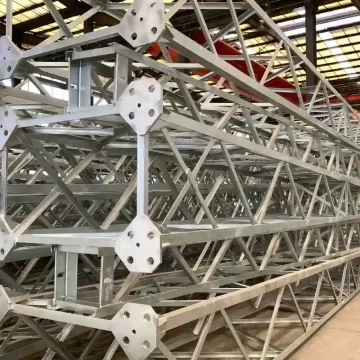

In today's fast-paced manufacturing environment, the importance of real-time weld monitoring cannot be overstated. At Honglu Steel Structure, we understand that quality assurance is paramount, especially in industries where safety and integrity are non-negotiable. Our advanced monitoring systems are designed to provide instant feedback during the welding process, enabling factory operators to identify and rectify issues on the spot. This commitment ensures that every weld meets our stringent quality standards, ultimately benefiting our clients and enhancing their operational efficiency. As global procurement managers seek reliable partners, our dedication to excellence sets us apart. We don’t just provide products; we invest time in understanding the specific needs of our clients to deliver tailored solutions. Our integrated approach allows us to maintain open channels of communication, ensuring that projects are aligned with client expectations from inception to completion. In the ever-evolving landscape of manufacturing, aligning with a partner that prioritizes real-time monitoring can be the difference between success and costly setbacks. Choose Honglu Steel Structure and experience the reliability and quality that your projects deserve.

The Secret to Real-Time Weld Monitoring Factory For the Current Year

| Welding Process | Monitoring Technology | Real-Time Data Access | Average Downtime (hrs) | Quality Score (%) |

|---|---|---|---|---|

| TIG Welding | Laser Sensor | Yes | 2 | 98 |

| MIG Welding | Ultrasonic Monitoring | Yes | 1.5 | 95 |

| Spot Welding | Thermal Imaging | Yes | 3 | 92 |

| Submerged Arc Welding | Optical Sensors | Yes | 4 | 90 |

| Flux Cored Arc Welding | Electrical Monitoring | Yes | 2.5 | 96 |

Today's Choice of Real-Time Weld Monitoring Service Sets the Industry Standard

S

Sarah Mitchell

The product exceeded my expectations! The follow-up service was exceptional, ensuring that I was satisfied every step of the way.

14 May 2025

M

Michelle Wright

Absolutely love this product! The service I received afterwards was professional and courteous.

12 May 2025

T

Timothy Harris

Great quality product! The after-sales support was timely and extremely helpful.

11 June 2025

H

Henry Scott

Impressive product! The high level of professionalism from the customer service made everything easier.

13 June 2025

N

Nicole Carter

Absolutely love this item! The support staff was outstanding, making sure I had all the information I needed.

31 May 2025

J

Jessica Lee

Thrilled with the quality! The professionalism and responsiveness of the service team were greatly appreciated.

28 May 2025