Comprehensive Guide to Steel Structure Fabrication: OEM Manufacturing Procedures

At HONGLU Steel Construction Group, we specialize in precision steel structure fabrication, ensuring that every project adheres to local regulations and client requirements through thorough design and planning. We prioritize high-quality materials, guaranteeing durability and strength in our products. Our state-of-the-art cutting and welding technologies allow for accurate fabrication of steel components, while our experienced team conducts rigorous quality control from start to finish. We commit to timely delivery, maintaining our standards without compromise. Whether for industrial, commercial, or residential applications, our custom steel structures are designed to meet your unique needs. Let’s work together to turn your vision into reality.How To Source Steel Structure Fabrication Procedure Guarantees Peak Performance Industry Giant

In the competitive landscape of steel structure fabrication, sourcing the right procedures is crucial to guarantee peak performance. At Honglu Steel Structure, we prioritize a customer-centric approach, ensuring that our operations not only meet but exceed industry standards. Our fabrication processes are strictly monitored and refined, allowing us to deliver high-quality structures that stand the test of time. Understanding the unique needs of each client is a cornerstone of our philosophy. We believe that successful partnerships begin with effective communication; thus, we actively engage with our clients to tailor our solutions to their specific requirements. This dedication to customization not only reinforces our commitment to excellence but also positions our clients for success in their respective industries. By choosing Honglu Steel Structure, global buyers can be assured of a reliable partner committed to delivering superior products and innovative solutions. As we navigate the complexities of the steel fabrication industry, our unwavering devotion to quality and performance sets us apart, ensuring that your projects are executed seamlessly and effectively.

| Procedure Step | Description | Expected Outcome | Performance Metrics |

|---|---|---|---|

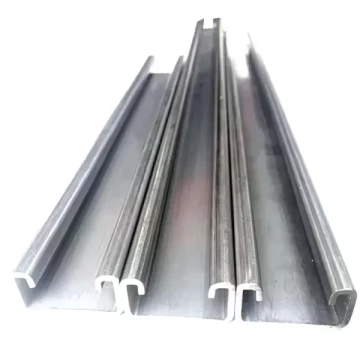

| Material Selection | Choose high-quality steel materials suitable for the structure's load requirements. | Ensure structural integrity and durability. | Material strength testing results. |

| Design Approval | Submit structural designs to engineers for review and approval. | Get timely approvals to avoid manufacturing delays. | Approval turnaround time. |

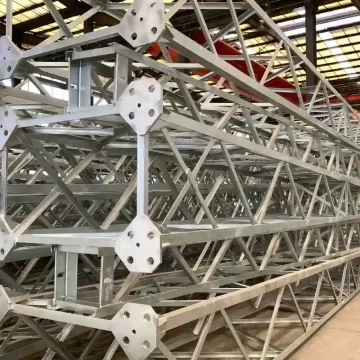

| Fabrication | Manufacture steel components according to specifications. | Produce precise and high-quality components. | Defect rates during fabrication. |

| Quality Control | Conduct inspections to ensure compliance with standards. | Identify and rectify defects before assembly. | Quality pass rates. |

| Assembly | Joint steel components following approved methods. | Ensure structural stability and strength. | Load-bearing tests. |

| Final Inspection | Perform a comprehensive evaluation of the assembled structure. | Confirm readiness for use. | Final inspection pass rates. |

Why Opt For Steel Structure Fabrication Procedure Outperforms the Competition Global Reach

K

Karen Perez

The product is exactly as described and of high quality. The after-sales team was insightful and friendly.

03 July 2025

P

Patricia White

This has been an excellent investment. The quality is outstanding, and the support staff is always ready to help.

09 May 2025

T

Thomas Young

Very high-quality product! It’s evident that the customer service team is well-trained and professional.

27 June 2025

P

Paul Lee

Exceptional quality! The after-sales service was proactive, ensuring that I was completely satisfied.

11 May 2025

J

Jennifer Turner

Thrilled with the quality! The after-sales support made the process seamless and enjoyable.

11 May 2025

J

Jennifer Martinez

Very satisfied with my purchase! The support staff was very well-informed and professional.

06 June 2025